PM

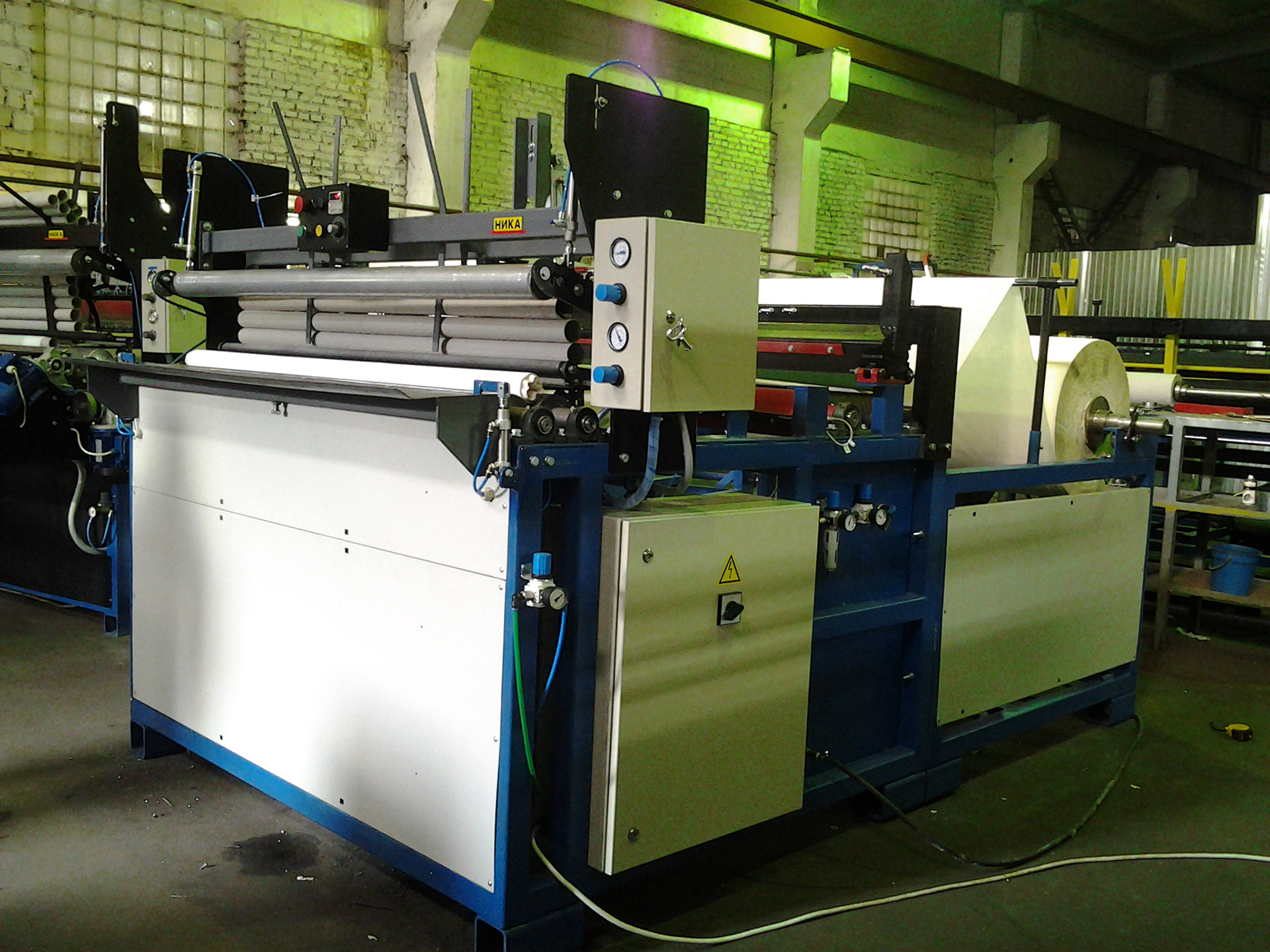

This semi-automatic machine is designed for the production of single-layer toilet paper and paper towels from recycled paper base for sanitary and hygienic purposes.

Winding is carried out both on cardboard sleeves and without them. The cardboard core is fed manually and after inserting it, by pressing the “Start” button, winding of the log of the required footage and density begins. The winding density is controlled by a pneumatically driven pressure shaft. After winding, the log is taken out by the operator and transferred to the next stage. The machine is equipped with an unwinding unit (with a conveyor drive), a three-shaft embossing system with mechanical clamping and a perforation unit. Pulley variators ensure reliable operation of all machine components, ensuring the specified linear speed. The reel with the base is loaded manually. However, at the customer's request, it is possible to install a pneumatic bobbin lifting device.

This machine is ideal for beginning manufacturers focused on producing products from waste paper raw materials for sanitary and hygienic purposes (waste paper base).

Price:

$12 000

Characteristics

Parameter | Value |

| Maximum width of unwinding reel, mm (format) | 1600 |

| Maximum diameter of unwinding reel, mm | 1200 |

| Inner diameter of the unwinding reel sleeve, mm | 76 |

| Maximum number of paper layers | 1 |

| Presence of perforation | yes |

| Number of embossing nodes | 1 |

| Speed, meters/min | 160 |

| Lifting the roll (reel) pneumatic | no |

| Automatic bushing feed | no |

| Automatic machine stop when paper breaks | yes |

| Tear-off sensor | yes |

| Metric counter | no |

| Automatic cutting and gluing with tail formation | no |

| Machine power, kW | 5.5 |

| Speed adjustment by frequency converter | yes |

| Pneumatic winding density adjustment | yes |

| Stitching unit | no |

| Overall dimensions (L/W/H), mm | 3,500/2,100/1,700 |

| Weight kg | 700 |