PM-4

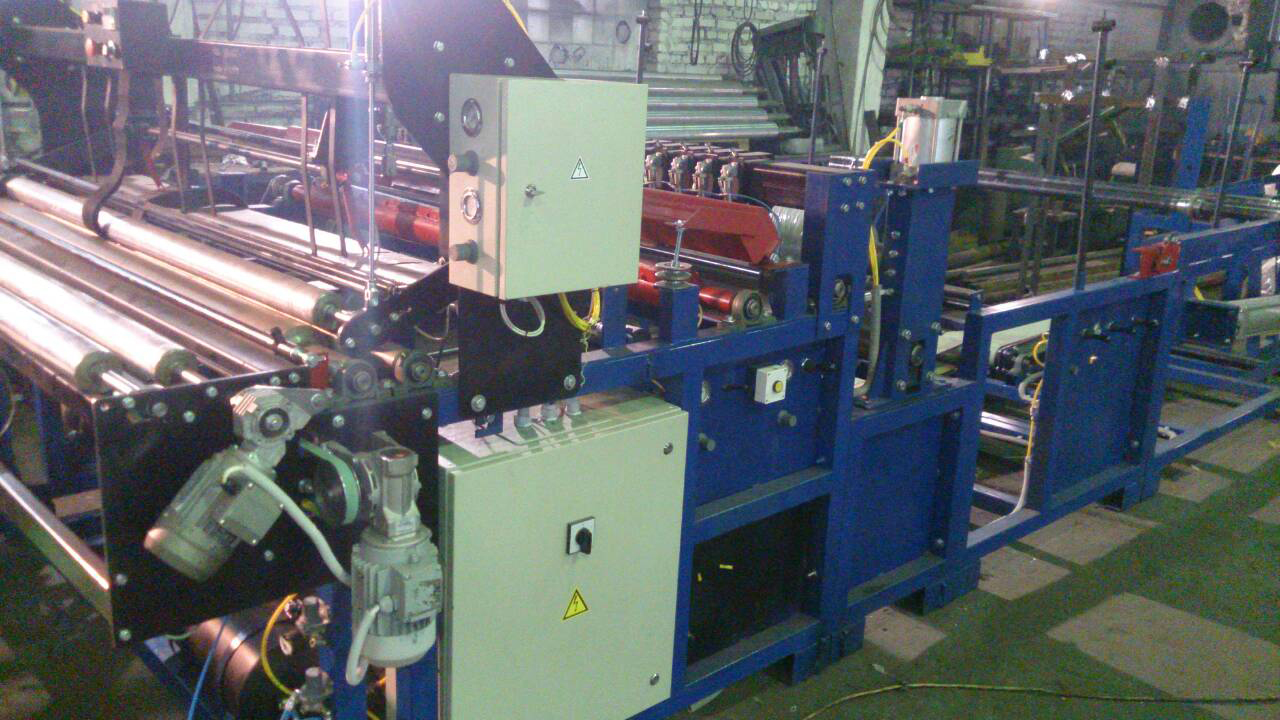

The automatic machine PM-4 is designed for winding single- and double-layer rolls of toilet paper and paper towels, both from waste paper and from cellulose base (raw materials). The layers are secured using a stitching unit.

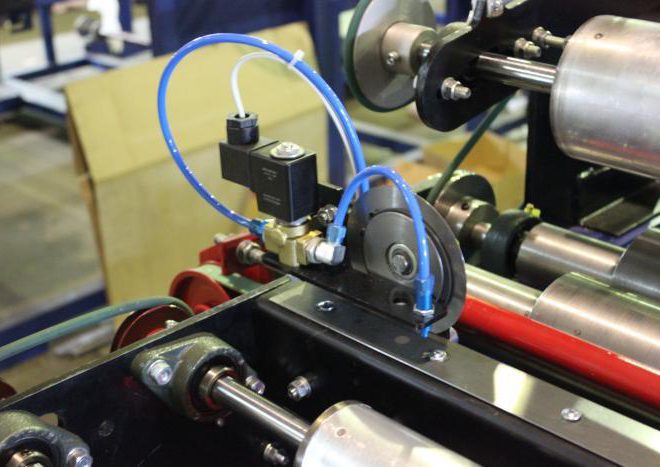

Unlike the PM-3 machine, this machine is equipped with a mechanical crepe unit (“stitching unit”), which allows two layers of paper to be bonded together more efficiently. The machine has a wide range of winding density adjustments through a pressure shaft driven by pneumatic cylinders. Also, the number and length of tear-off sheets in a roll, be it paper towels or toilet paper, is regulated. The log is cut using a “running knife” unit, which simultaneously with cutting the paper applies a layer of glue, which allows you to form a tear-off tip on the finished rolls. The machine is equipped with sensors for paper breakage, log winding and a tear-off sensor.

The overall speed of the machine is controlled automatically. For an emergency stop of the machine, a paper break sensor is provided.

*The coreless winding unit is an additional option. Cost – $500

PM-4 is universal in use and allows you to produce a wide range of products on one machine (it involves working with a base of cellulose and waste paper, allows you to produce jumbo rolls for a dispenser), which is an important factor for beginning entrepreneurs.

Price:

$36 000

Characteristics

| Parameter | Value |

| Maximum width of unwinding reel, mm (format) | 1600 |

| Maximum diameter of unwinding reel, mm | 1200 |

| Inner diameter of the unwinding reel sleeve, mm | 76 |

| Maximum number of paper layers | 2 |

| Presence of perforation | yes |

| Number of embossing nodes | 1 |

| Speed, meters/min | 190 |

| Pneumatic lifting of the roller | yes |

| Bushing feed | automatic |

| Automatic machine stop when paper breaks | yes |

| Tear-off sensor | yes |

| Metric counter (at customer's request) | yes |

| Automatic cutting and gluing with tail formation | yes |

| Machine power, kW (380V) | 18.0 |

| Speed adjustment by frequency converter | yes |

| Pneumatic reduction/spreading all shafts | yes |

| Stitching unit | yes |

| Overall dimensions (L/W/H), mm | 6500/2100/1900 |

| Weight, kg. | 3500 |