PM-6

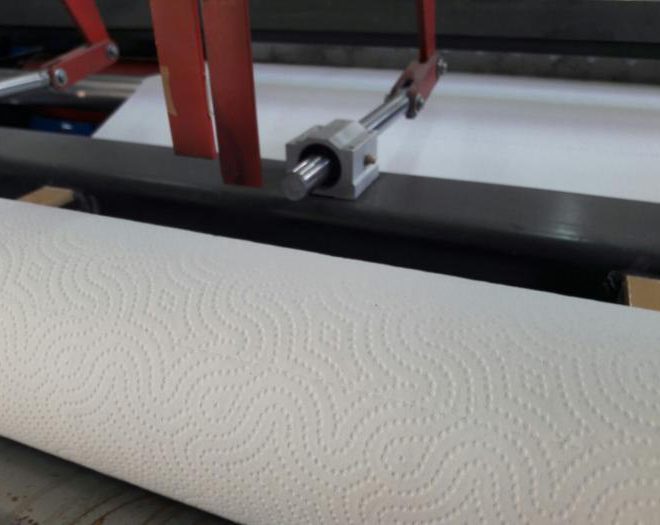

Designed for the production of two- and three-layer toilet paper and paper towels with different prints of premium quality from cellulose raw materials.

The lamination unit glues layers of paper with different prints together. This method of fastening layers of paper allows us to produce products of the highest quality, which can be classified as elite.

The linear speed at all nodes is regulated by electronic variators, and the unwinding speed is regulated by a distance sensor. Synchronization of the winding unit and the embossing unit is carried out using encoders. The overall speed of the machine is controlled automatically. For an emergency stop of the machine, a paper break sensor is provided.

At the customer's request, embossing can be done with any design.

Price:

$65 000

Characteristics

| Parameter | Value |

| Maximum width of unwinding reel, mm (format) | 1600 |

| Maximum diameter of unwinding reel, mm | 1200 |

| Inner diameter of the unwinding reel sleeve, mm | 76 |

| Maximum number of paper layers | 3 |

| Presence of perforation | yes |

| Lamination unit | yes |

| Number of embossing nodes | 2 |

| Speed, meters/min | up to 190 |

| Loading a reel with base | pneumatic |

| Bushing feed | automatic |

| Automatic machine stop when paper breaks | yes |

| Tear-off sensor | yes |

| Metric counter (at customer's request) | yes |

| Automatic log cutting and tail formation | yes |

| Motor power, kW (380V) | 20.75 |

| Speed adjustment by frequency converter | yes |

| Lamination unit | yes |

| Overall dimensions (L/W/H), mm | 8050/2600/1900 |

| Weight, kg. | 6200 |